Hydraulic control valves are important components in hydraulic programs, offering as the important thing regulators of fluid movement, force, and direction. These valves perform an essential role in a wide selection of programs, from industrial equipment and construction equipment to aerospace and automotive systems. The basic principle behind hydraulic get a grip on valves lies in their power to handle the flow of hydraulic water in just a process, allowing for precise control and adjustment of varied components.

One of the major operates of hydraulic get a grip on valves would be to control the pressure within a hydraulic system. Force control valves, such as for instance comfort valves, make certain that the pressure stays within secure functioning limits, avoiding potential injury to painful and sensitive components. This is specially important in programs where sustaining a particular stress level is critical for optimal efficiency and safety.

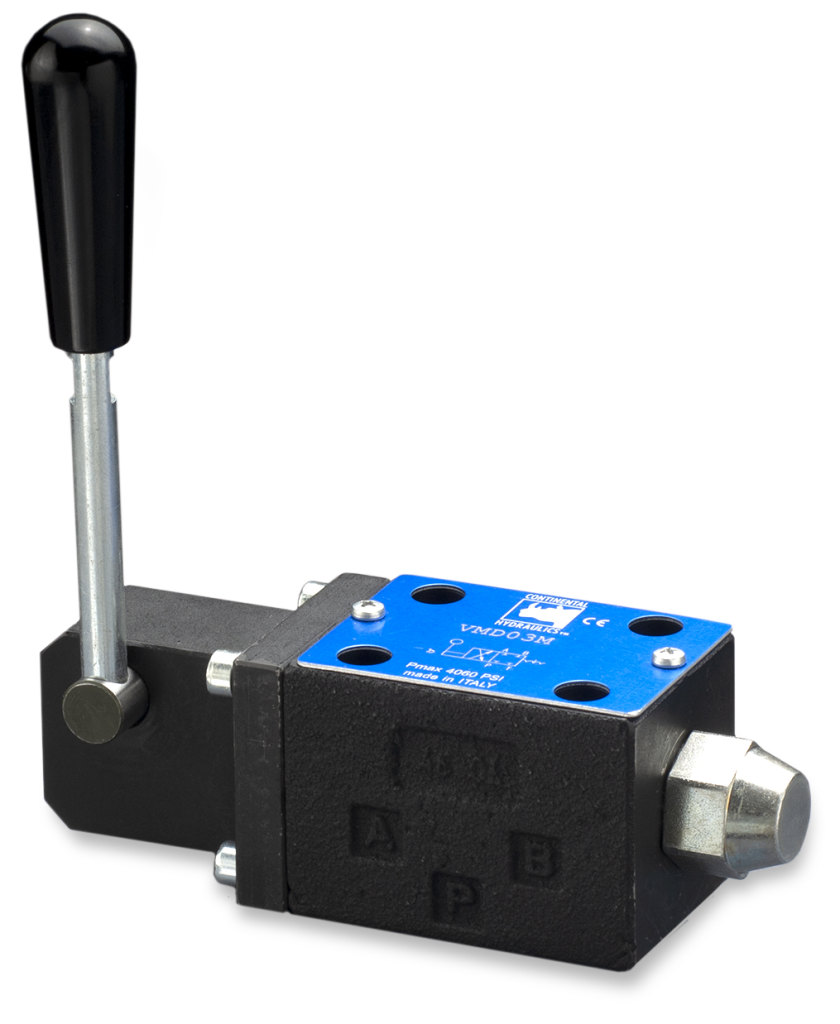

Online get a grip on valves are still another crucial sounding hydraulic control valves. These valves determine the path of substance movement within the device, allowing the managed motion of hydraulic actuators. Whether it’s the extension or retraction of a hydraulic tube or the turning of a motor, directional get a grip on valves govern the routes by which hydraulic water moves, dictating the action of the connected machinery.

Hydraulic get a handle on valves are made with a variety of control elements, including manual, technical, and electro-hydraulic. Guide valves enable hands-on control, mechanical valves answer external forces or technical inputs, and electro-hydraulic valves control electric signs for precise and automatic control. That range in control possibilities makes hydraulic methods adaptable to various detailed needs and user preferences.

Effectiveness is really a crucial factor in hydraulic techniques, and hydraulic control valves play a essential position in optimizing performance. Proportional get a handle on valves, for example, help fine-tuned adjustments to water movement charges, allowing for accurate control over the rate and force of hydraulic actuators. This degree of get a grip on promotes over all system performance, reducing energy waste and ensuring optimal operation.

In addition to their main features, hydraulic get a grip on valves donate to system safety. Force reduction valves act as fail-safes, defending the system from overpressure and possible damage. The receptive character of the valves assures that, in case of a stress spike, hydraulic liquid is diverted properly, stopping catastrophic problems and safeguarding both the apparatus and personnel.

The preservation of hydraulic get a grip on valves is vital for experienced process performance. Normal inspections, washing, and lubrication are essential to stop wear and control valves , leaks, and different issues that might bargain the functionality of the valves. Timely preservation not merely runs the lifetime of the valves but additionally ensures the consistency of the entire hydraulic system.

Development in hydraulic get a handle on device engineering remains to improve, with the integration of digital and smart technologies. Digital get a handle on products (ECUs) help accurate and programmable get a grip on over hydraulic programs, starting avenues for automation, distant monitoring, and predictive maintenance. As industries move towards Industry 4.0, the position of intelligent hydraulic get a grip on valves becomes increasingly crucial in making interconnected and intelligent hydraulic systems.

In summary, hydraulic get a handle on valves would be the unsung people of hydraulic methods, providing the necessary get a handle on and regulation for the efficient operation of various machinery and equipment. Their versatility, detail, and share to process protection make sure they are fundamental in industries where hydraulic energy is harnessed for an array of applications. As technology remains to advance, hydraulic get a grip on valves will probably perform a much more advanced role in shaping the continuing future of hydraulic techniques across diverse sectors.

Leave a Reply